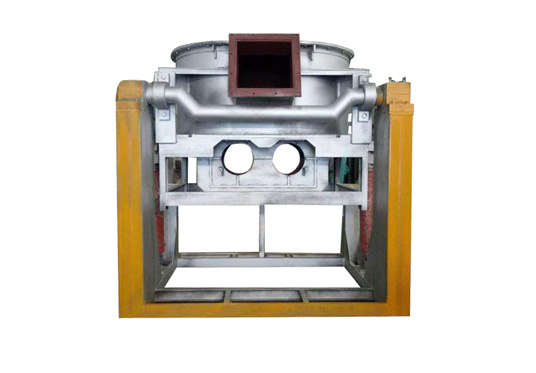

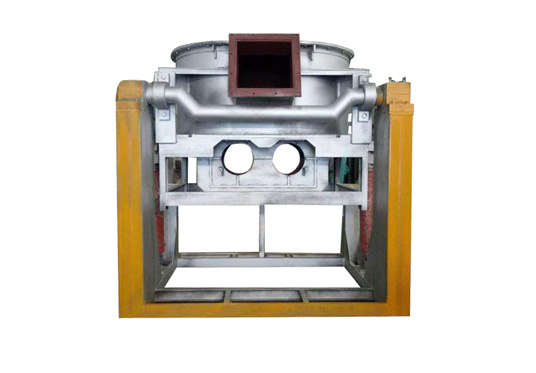

Induction tilting furnace

Hydraulic dumping furnace is designed on the basis of electromagnetic induction principle. After the induction coil electrified, alternating magnetic flux is generated. It passes through the iron core to form a closed magnetic circuit. This alternating magnetic flux induces electromotive force and secondary current in the melting channel. This current converts electrical energy into heat energy through the resistance of the metal furnace material , which melts metal in melting channel.

Products Description

Induction tilting furnace:Hydraulic dumping furnace is designed on the basis of electromagnetic induction principle. After the induction coil electrified, alternating magnetic flux is generated. It passes through the iron core to form a closed magnetic circuit. This alternating magnetic flux induces electromotive force and secondary current in the melting channel. This current converts electrical energy into heat energy through the resistance of the metal furnace material , which melts metal in melting channel.

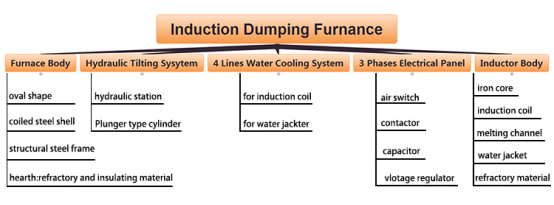

Product Composition

①Furnace body ② inductor ③ hydraulic tilting system ④ water cooling system ⑤ electrical panel

Main Parameters

| Model | BTQD-300KG | BTQD-500KG | BTQD-750KG | BTQD-1000KG | BTQD-1500KG | BTQD-3000KG |

| Rated power(KW) | 75 | 120 | 200 | 250 | 400 | 600 |

| Melting rate(KG/H) | 300 | 500 | 750 | 1000 | 1500 | 3000 |

| Furnace volume(T) | 2 | 2 | 3 | 3.5 | 4.5 | 5.5 |

| Nominal voltage(V) | 380 | |||||

| Phases | 3 | |||||

| compensated power factor | 0.9-1.0 | |||||

| cooling type | Water cooling | |||||

| cooling water pressure | 0.3~0.4Mpa | |||||

| cooling water consumption | 3.0Nm3/h | |||||

| furnace controlling temperature | 1180~1250℃ | |||||

| angle of inclination | 95º | |||||

| speed of inclination | 1200mm/min | |||||

Why Choose Us

Product advantages:

- Higher melting efficiency,Greatly saving power,Compact structure with larger capacity.

- Low temperature, No Gas, No polution. Easy & safe operation.

- Faster heating-up temperature. Temperature easy to control, Higher productivity.

Pre-sale service:

- Free technical consult

- Free parameter details

- Field/video factory visit support

- New customer discount

- Human online service

After-sales Service:

- 1 Year warranty

- Field installation & inspection

- Available engineer overseas instruction

- Operation training

- Discounted spare part

FAQ

-

How do you control the quality of your products?

We are manufacturer with our own factory, so it is convenient for one-stop production and inspection. There are experienced engineers and professional QC team in our company. The quality is definitely reliable.

-

What is your lead time?

About 60 working days after received the deposit.

-

How long can I get started to producing finished goods?

Around 5 months. After 60 days manufacturing, there is another 60 days for workshop construction and equipment installation.When start the melting furnace to melt copper, it still needs nearly 30 days. Then the machine line can cast bright copper rod.

-

What kind of services do you have?

We promise Presale service:

Free Technical Consult

Parameter Details

Field or video factory visit support

Timely Human Online Service

After-sale service:

1 Year Warranty

Available Engineers Oversea Training

Field Installation/ Operating Instruction

Discounted Spare Parts And all of these has been covered in the quotation.