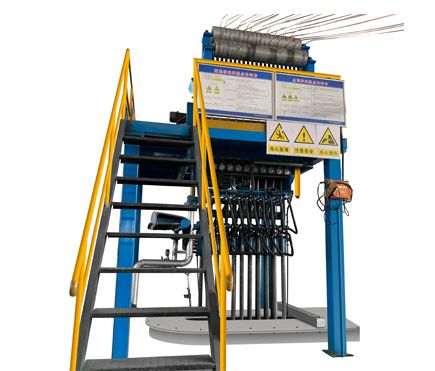

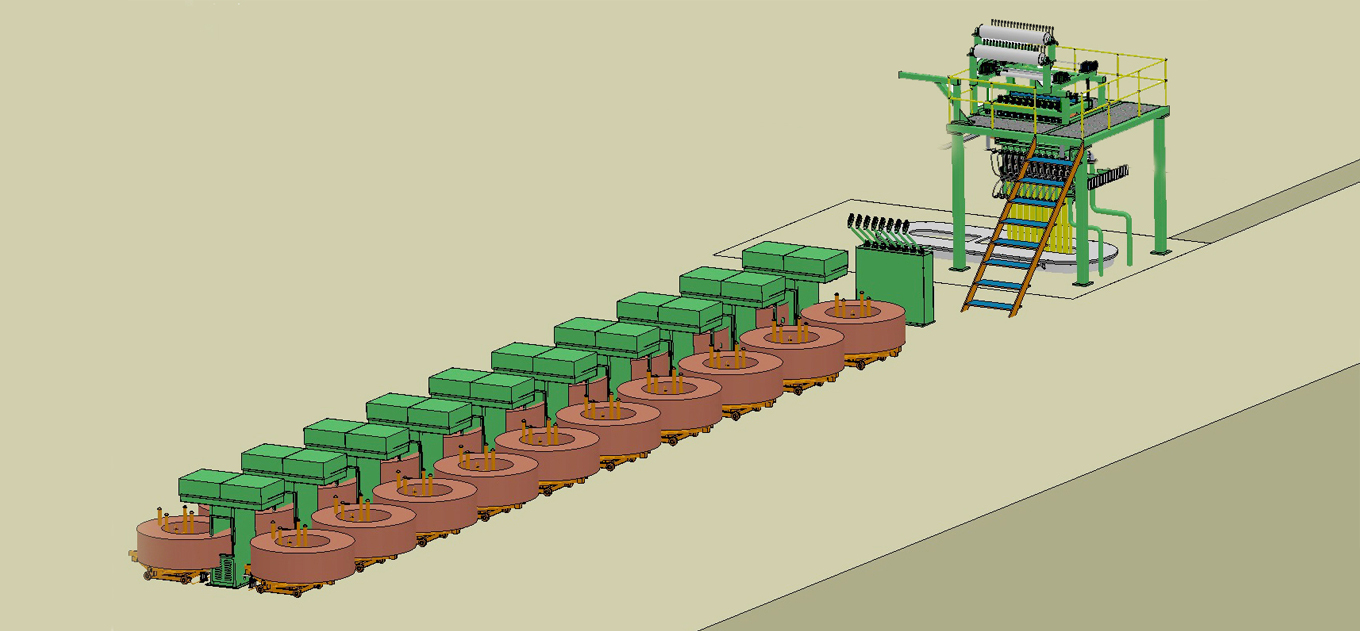

8-20m copper rod upwards casting machine

Copper rod upcasting machine use cathode copper or scrap copper as raw material, to produce oxygen-free copper rod/ strip(foil billet)/tube. Besides, customization is provided.

Products Description

Copper rod upcasting machine use cathode copper or scrap copper as raw material, to produce oxygen-free copper rod/ strip(foil billet)/tube. Besides, customization is provided.

Main Parameters

| Model | Strand | Dia.(mm) | Speed | Annual Capability | Driver | Power consumption | Installation capacity |

| SYLZ-1000T | 2 | 8-20 | max3.2m/min | 1000 tons | double servo | 100kw | 160KVA |

| SYLZ-2000T | 4 | 8-20 | max3.2m/min | 2000 tons | double servo | 160kw | 220KVA |

| SYLZ-3000T | 6 | 8-20 | max3.2m/min | 3000 tons | double servo | 220kw | 300KVA |

| SYLZ-5000T | 10 | 8-20 | max3.2m/min | 5000 tons | double servo | 290kw | 330KVA |

| SYLZ-6000T | 12 | 8-20 | max3.2m/min | 6000 tons | double servo | 300kw | 350KVA |

| SYLZ-8000T | 14 | 8-20 | max3.2m/min | 8000 tons | double servo | 400kw | 500KVA |

| SYLZ-1000T | 16 | 8-20 | max3.2m/min | 10000 tons | double servo | 450kw | 60KVA |

| SYLZ-10000T | 20 | 8-20 | max3.2m/min | 12000 tons | double servo | 480kw | 600KVA |

| SYLZ-15000T | 24 | 8-20 | max3.2m/min | 15000 tons | double servo | 700kw | 900KVA |

Working Process

-

Cathode Copper Plate

-

Melting Furnace

-

Upwards Casting Machine

-

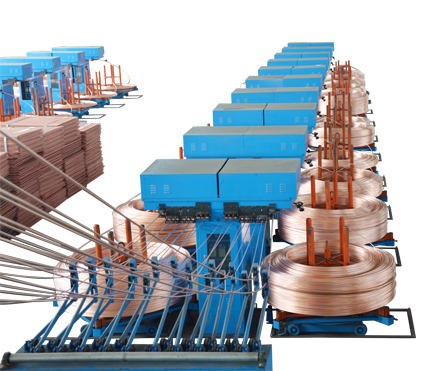

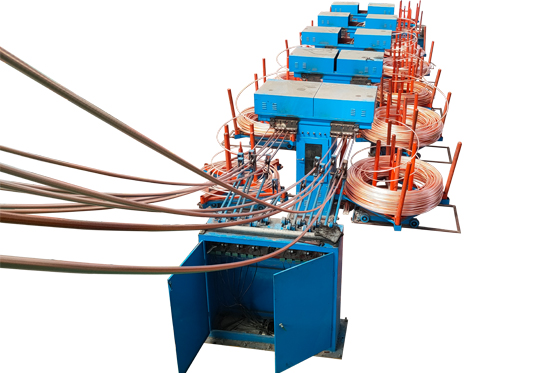

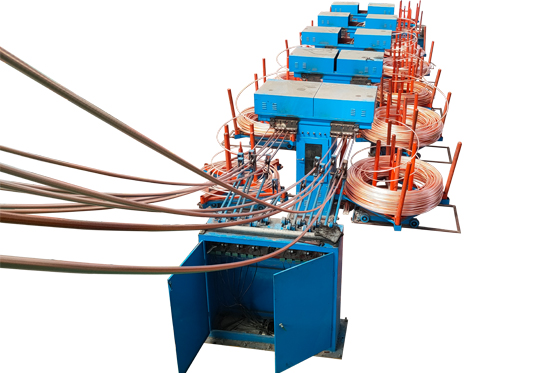

Finished Copper Rod Coil

- Prepare the raw material - cathode copper or copper alloy.

- Melting the copper cathode to liquid through the melting furnace, separate it from the air by a layer of charcoal or graphite flakes at the same time.

- Keeping the copper in liquid situation at the holding furnace with the temperature of 1150℃±10℃.

- Copper liquid is rapidly crystalized by in the graphite mold, continuously casting copper rods.

- The final step will be completed by double-strand take-up machine and other auxiliary equipment.

- Annual capacity of a single machine line is from 1000 tons to 15000 tons

Details Images

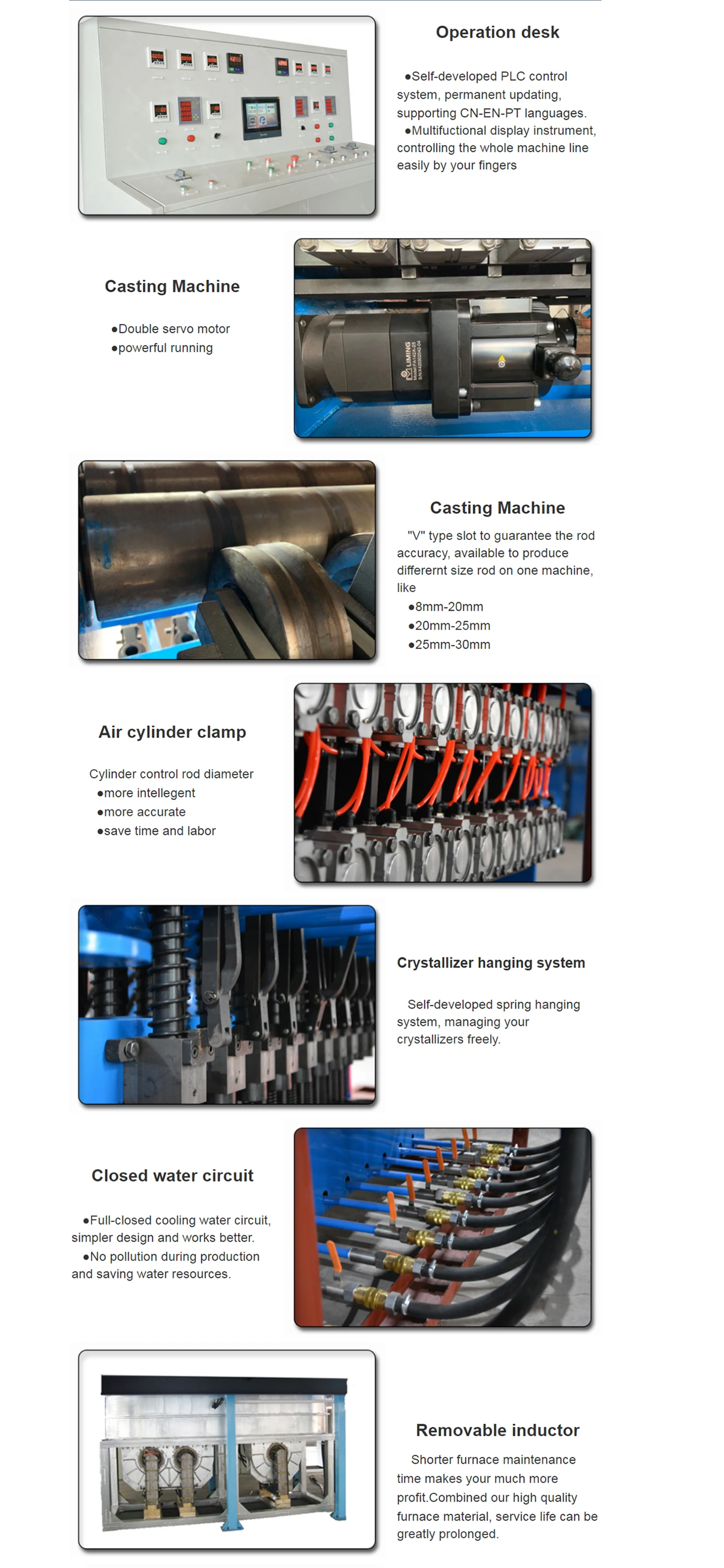

Product Details

Finished Products

Finished products by upcasting machine can be:

- Copper rod

- Copper strip/foil billet

- Copper tube/pipe billet

Packing&Shipping

FAQ

-

How do you control the quality of your products?

We are manufacturer with our own factory, so it is convenient for one-stop production and inspection. There are experienced engineers and professional QC team in our company. The quality is definitely reliable.

Send us a message

Related Products

nodata